Taiichi Ohno

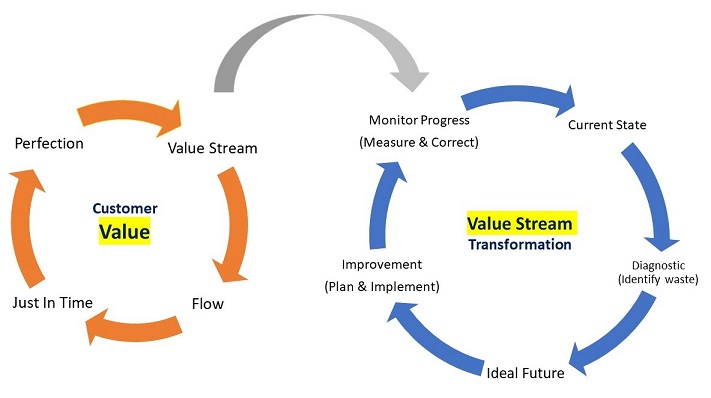

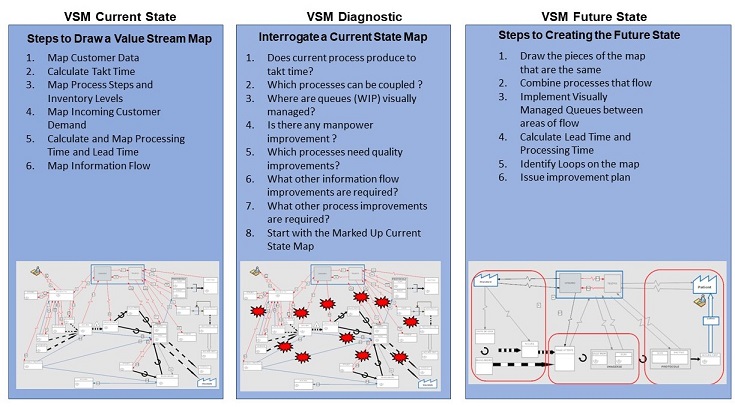

All we are doing is looking at the time line, from the moment the customer gives us an order to the point when we collect the cash. And we are reducing the time line by reducing the non-value adding wastes.

Therefore, we need to focus on the value chain first. Let it flow without constraint to deliver on time the value at the best price, with the expected quality requirement.

For achieving perfection over time, continuous improvement strategy is required.

created with

Website Builder Software .