Practice is our Know-How.

Communication is our Art of Clearly Transferring Theoretical Knowledge

The success factor is the « Learning By Doing »

Best Approach of Transferring Years of Experience and Know-How

We Customize Practical Training

During our life, we change jobs several times.

Professional continuing education is an essential step to change jobs or evolve in your company.

This type of training gives you the skills needed to perform a new job.

Most job changes require continuous improvement and process optimization skills.

Firms that promote operational excellence must act in this direction

We Support Projects Implementation

The implementation of continuous improvement projects is based on field experience.

We conduct all field activities with:

- Stand up meeting.

- KPIs and action items Dashboard.

- Live coaching.

No theoretical presentations, only note taking. Our experience reveals that powerpoints do not generate added value (According to the LEAN principles).

WASTE IS NOT ALLOWED

We Train Individuals on Request

We apply the « Train the trainer » principles:

- We communicate better and avoid heavy training lessons (Learning by doing).

- We avoid repeated and boring comments (Just useful experiences).

- We refer to exactly how people learn (apply operational pedagogy).

- We give responsibility as well as training (Live coaching).

- We continue to foster learning and development.

- We strive to know our audience.

Therefore a specification is established to frame the learning and prepare the appropriate tools

Experience

The know-how of our Keeplean experts is based on several years of experience in both training and support the implementation of Lean Six-Sigma transformation projects.

Knowledge transfer is our strength: From practical training to the implementation support.

An international reputation in the mining sector (Bhp Billiton: South Africa – Mozambique – Australia) as well as other European structures in the field of logistics, health and manufacturing. This experience has made us a valuable organization.

We have supported more than 100 projects in continuous improvement (between 2005 and 2022), and certified more or less 80 practitioners in Lean Six-Sigma from theoretical training to the implementation of strategic transformation projects.

The Method: Practical training steps to learn how to manage a continuous improvement project in the real world

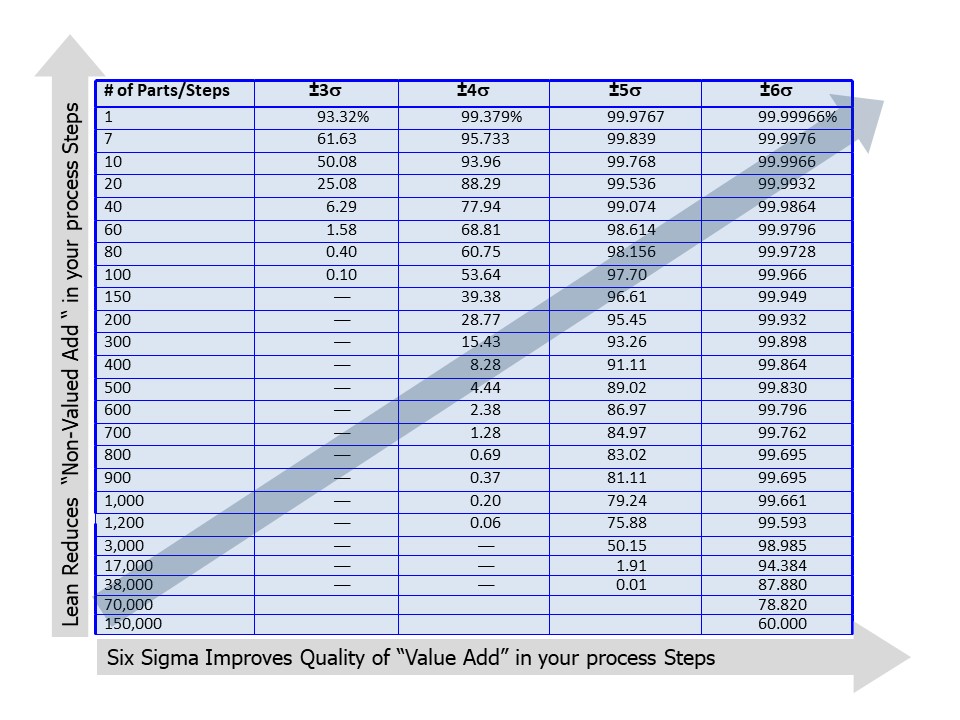

Target Towards Six-Sigma

The Goal (6σ Quality Level).

Going from 3σ to 6σ is a long way and requires pragmatism.

However:

We must get rid of activities that do not add value

and optimize value-added activities.

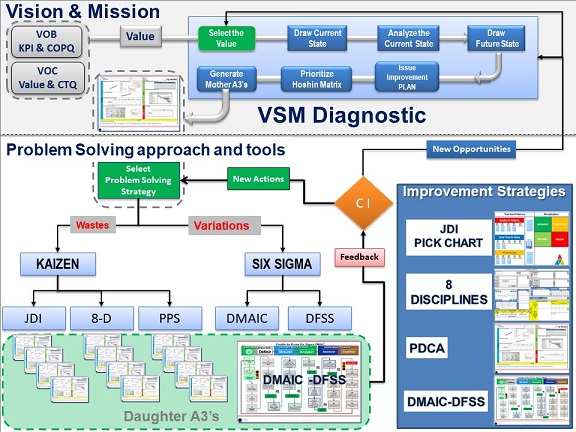

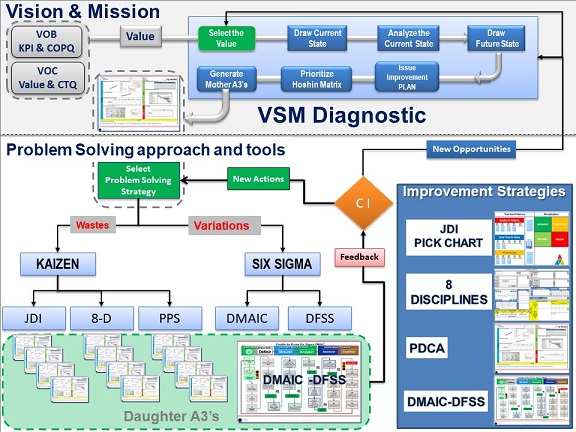

Vision & Mission

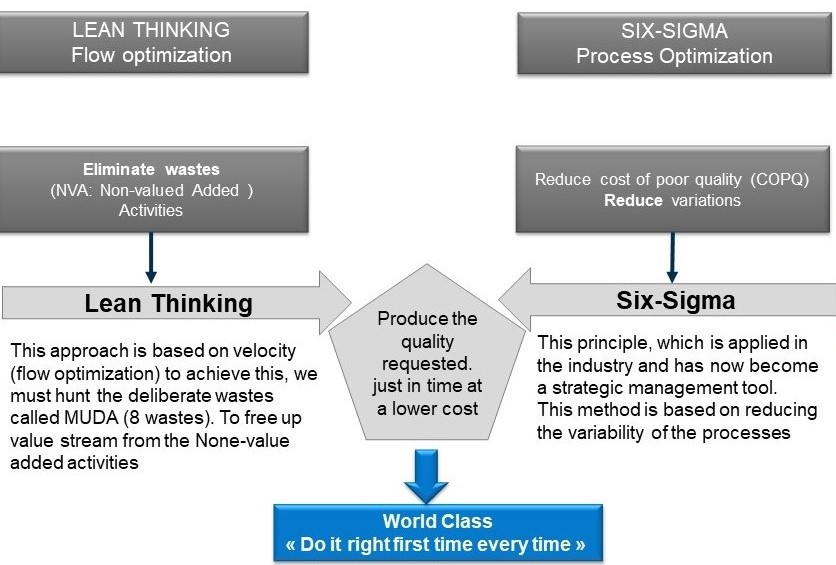

LEAN Thinking

- Get rid of None value added activities (Eliminate waste).

- Optimize Value added activities by reducing process variability (Reduce Cost Of Poor Quality)

Reduce Cost Of Poor Quality = Reducing operational costs and increase Profit

Transformation Strategy Roadmap

Pragmatic Approach

Using your theoretical knowledge to lead a project successfully

The roadmap guides you through the steps for implementing continuous improvement.

This pragmatic method is different from the acquired theory full of case study information.

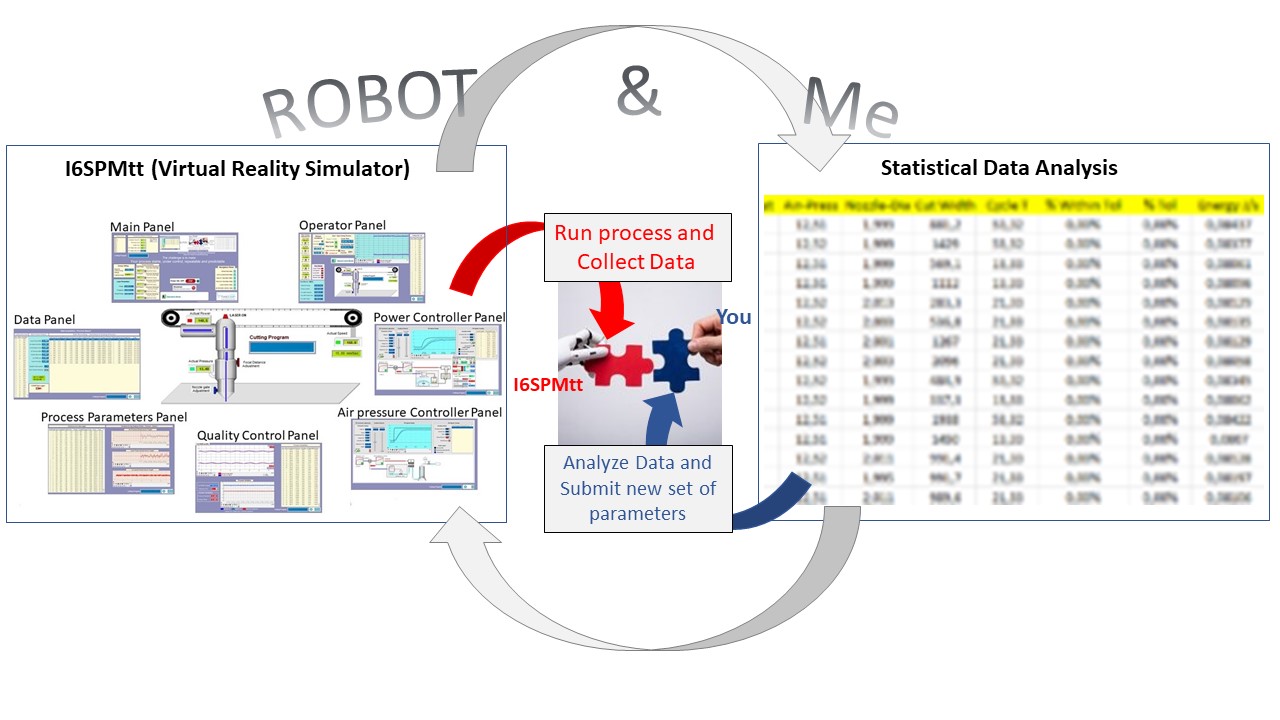

The Concept: The training materials are based on interactive simulators and workshops (Assembly and manufacturing)

Phone

+352 691

Address

3, Rue principale

L-8814 BIGONVILLE

LUXEMBOURG

Business Hours

Monday to Friday

10:00 – 18:00

LUXEMBOURG VAT: LU33413630

Autorization N° : 10128062 /0 /1

RCS: B258159